Leo company's product prototype.

Leo Membrane Filter Press:easy Filter PressOperation and Automatic Filter Press Working

Membrane Filter Press Working Principle VS.Plate and Frame Filter Press Working Principle

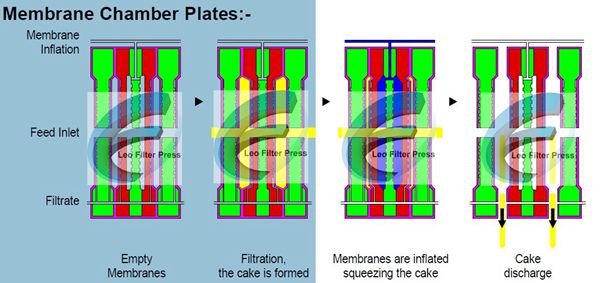

Leo Filter press offers different size ofmembrane filter plates. Among all the filter press plates, the membrane filterplates can help reduce filtering cycle time and help client to get dryer filtercakes. The Membrane Filter Press Working Principleand Membrane Filter Press Operation: How does a filter press work? The filter press is a main solid liquidseparation equipment for filtering, the working principle is simple and eventhe automatic filter press also easy to be operated.The filter press will workby a feeding pump which will inlet slurry to filter press chambers continuouslywhen the chambers are full, the filter press will open to dump out all thefilter cakes produced in the filtration. Membrane Filter Plate Size: from 400mm to2000mm Membrane Filter Plate Membrane Material:Rubber or PP Membrane Squeezing Pressure: from 6bar to20bar Membrane Filter Press Capacity: from 1L to20cbm Membrane Material Quality: High quality forexporting standard Testing Method: air or water and inflatedmembrane sheets for membrane squeezing pressure endurable test

Hangzhou Leo Filter Press Co.,Ltd.

Hangzhou Leo Filter Press Co.,Ltd.