Leo company's product prototype.

Membrane Filter Press Working Principleand Operation Instructions-Leo Filter Press Co.,Ltd.

Leo Filter Press Automatic Membrane Filter Press System Operation|How Does a Filter Press Work

When Leo Filter Press delivers the finished order, all the detailed operation instructions will be sent with the filter press to the end user,here is the working and operation instructions for Leo Filter users for reference.Filter press type: full automatic membrane filter press

Feeding pump:big size slurry pump

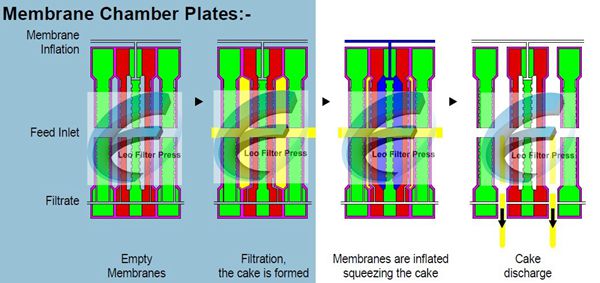

Filter press working steps:

1. Complete manual operation test:

Set to manual operation,manual start feeding pump for slurry feeding,check the feeding valve can be opened automatically, during this step check slurry pump feeding pressure

Manual membrane squeezing: open squeezing tank valve, press down “membrane squeeze” button, start the membrane squeezing pump, after squeezing, stop squeezing pump,during this operation, check squeezing pressure and make sure it will not higher than the upper limit.Manual filter press open: after membrane squeezing,open filter press, the oil pump will start to full the low pressure oil chamber to withdraw the piston to open filter press;Manual cake discharging: after filter press opening, start plate shifting, the shifters will move to every filter plate to move the filter plates to discharge filter cakes.If no cake remained solids on the filter cloth,please make sure to clean the filter press cloths,then press the filter press again for next filtering cycle operation.

2. Automatic operation

Press down “automatic operation” button to carry out automatic opration.

The set cycle time is feeding for 1 hour, membrane squeezing for 20 minutes, cake shifting for 10minutes, all the steps will be finished in 2hours

Membrane Operation and Maintenance Remarks:

1. Don’t stand at the behind of the hydraulic cylinder

2. Check filter press cloth surface,or the filter plates will be damaged during filter press closing

3. Check all the automatic valves during operation

4. Filter press cloth washing

5. Clean filter press surroundings,necessary lubrication for the filter press parts

6. Hydraulic oil level checking

Hangzhou Leo Filter Press Co.,Ltd.

Hangzhou Leo Filter Press Co.,Ltd.