Leo company's product prototype.

Plate and Frame Filter Press Operation Instructions from Leo Filter Press,Filter Press Manufacturer from China

Plate and Frame Filter Press Design and Working Operation Tips for Leo Filter Press Plate and Frame Filter Press Users

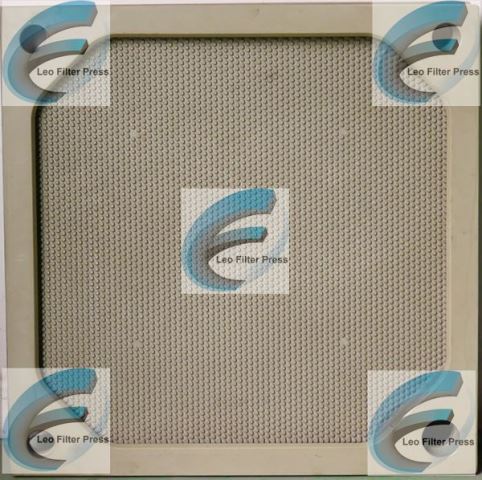

Filter press plate and filter press frame is the basic spare part for the plate and frame filter press,it consists from the following parts:

1. closing surface

the closing surface is a square top surface for filter plate and filter frame,the chamber sealing ability guaranteed from the sealing surface,so in the "plate and frame filter press technical requirements"given each size of filter plate and filter frame closing surface Parallelism and flatness

2. suspension feeding hole

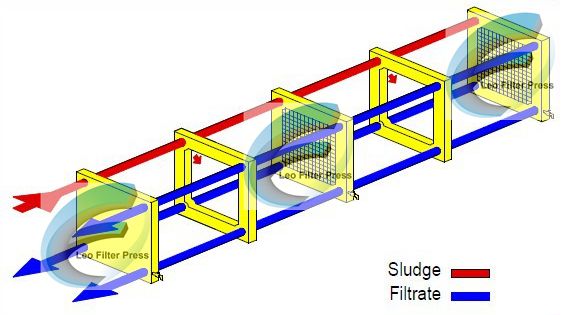

at the pre-setting hole for the filter plate and filter frame,there is a the same hole with the same size,when all the filter plate and filter frame are closed,all the holes will be connected to form a filtrate discharging channel,and also connect with slurry feeding hole on the tail plate of the filter press frame.

3.filtrate discharging hole

the filtrate discharging hole will be connected with filtering surface gutters,for the open discharging filter press,this hole will directly connect the watertap on the filter plate,for closed discharging filter press,there is a hole on both filter plate and filter frame,all of them will connect together to conncect with the discharging hole on the tail plate of the filter press frame,all the filtrate will flow into drainage pipe or tank through this end hole.

4. washing water inlet hole nd washing water outlet hole

if the filter cake in the filter chambers need to be washed from washing holes with washing liquid, washing water will flow out from another filter plate filtrate releasing hole

5. supporting handles for filter plate and filter frame

there will be supporting handles for the filter plate and filter frame,by this handles,all the filter frame and filter plate can be put on the side bars and slide on it for filter cake dumping ,when discharging filter cakes,the filter plate handles become movable part or the filter press operators

6. position setting gutter

this part between filter plate handles and filter press side bars,by an across block setting to guarantee all the holes for filtrate discharging,washing water inlet and outlet,suspension feeding can be on the same line and connect together completely

for filtering surface function is for filter cloth supporting and guide filtrate flowing out,on the filtering surface there are lots of channels for filtrate outlet,those channels and points will consist different faces which will not result in filtering result

Leo Filter Press offer various size plate and frame filter press,filter plate and filter frame size from 300mm(small size testing filter press) to 1500mm,chamber volume from 10L to 5000L

Plate and frame filter press pressing method: automatic hydraulic system for middle and big size filter press;manual hydraulic system for small size filter press

Filter press cloth: various filtering mesh and filter paper available

Filter press pump:screw pump, diaphragm pump(membrane pump),slurry pump and other food grade centrifugal pump

Hangzhou Leo Filter Press Co.,Ltd.

Hangzhou Leo Filter Press Co.,Ltd.