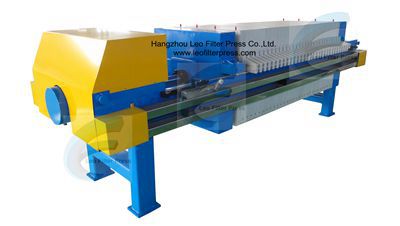

Leo company's product prototype.

Concentrate Dewatering Processing Filter Press from Leo Filter Press,Concentrate Filter Press Manufacturer from China

Leo Filter Press Mining Concentrate Dewatering System High Efficiency Concentrate Filter Press Instructions

For mining concentrate dewatering,filter press is the normal dewatering filtration equipment,such as zinc concentrate,copper concentrate,iron concentrate,nickle concentrate etc,products dewatering.

During those concentrate dewatering, there will be a large sum of water consumption for washing to purify filter cake after filtering.

The capacity of those concentrate filter presses are normally bigger than the sludge dewatering filter press for wastewater dewatering,for big size filter press operation, there are various automatic system for less filter press operation intensity, such as automatic filter plate moving system for concentrate cakes discharging,automatic filter cloth washing system,automatic filter cloth vibrating system, automatic drip tray system etc.

Concentrate filter press plate size:from 400mm small size testing filter press to 2000mm big size plates

Concentrate filter press chamber volume:10L to 20000L

Filter press cloth: filter cloth specially for concentrate filtering

Filter press types for concentrate filtering: recessed plate filter press,diaphragm filter press(membrane filter press) or plate and frame filter press

Filter press feeding pump for concentrate dewatering:diaphragm pump,screw pump, slurry pump

For filter press feeding pump, if uses for a long time, there will be abrasion during filter press feeding,especially for the concentrate feeding,if there is less feeding capacity, check the feeding pump whether there is less feeding pressure which caused by the feeding abrasion,as the 70% concentrate feeding time is just feeding and pushing concentrate to the chambers,the last 30% feeding time is the most important for high pressure dewatering.

Hangzhou Leo Filter Press Co.,Ltd.

Hangzhou Leo Filter Press Co.,Ltd.