Leo company's product prototype.

Leo Filter Press Membrane Filter Press

Membrane filter press is very popular among the filter press users. Now Leo Filter Press offers one piece polypropylene membrane filter plates(fixed membrane filter plates)  and detachable rubber membrane filter plates

and detachable rubber membrane filter plates , by membrane squeezing we can reduce filter cycle time.

, by membrane squeezing we can reduce filter cycle time.

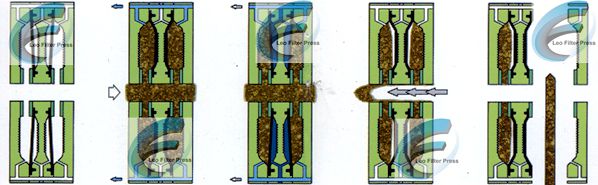

How does the membrane filter press works?

All the membrane sheet will be inflated by water or air, if you want to run your filter press in a shorter time, then membrane squeezing will be the wise choice. When squeezing, the membrane plates will be inflated and to reduce the filter cake moisture content.

Why membrane filter press?

Reduce filtering cycle time

Improve filter cake washing

Less moisture content

Membrane filter press instructions:

Operation: automatic or semi-automatic

Membrane /Chamber Filter plate size: 400mmX400mm,800mmX800mm,1000mmX1000mm,1200mmX1200mm,1250mmX1250mm,1500mmX1500mm,1500mmX2000mm,2000mmX2000mm

Filter plate quantity: 10pcs to 150pcs

Designed treating capacity: 15L to 20000L

Max membrane squeezing pressure: 16bar

Filtering area: 1m2 to 1000m2

Cake thickness: 30mm-40mm

Draining method: open/closed

The options for the filter press system:

Bomb door drip tray

Filter cloth washing system

Filter cloth shaking system

Cake delivery system

Country of Origin: China

Capacity per year: 1000sets

Membrane type: fixed one piece type polypropylene membrane filter plate and replaceable rubber membrane filter plate

Certificate: CE, ISO

Condition: 100% new

Feeding pump available: according to slurry condition, Leo Filter Press offer different kinds of feeding pumps, such as screw pump, pneumatic pump(membrane),piston pump,piston membrane pump, hose pump etc.

Please contact us if you need further instructions for your membrane filter press working and membrane filter plates selection.

Membrane Filter Press Application:

Palm oil, municipal wastewater, leather producing wastewater, textile wastewater, the wastewater from WWTP, the sludge from chemical producing factories, pigment, dyestuff, sugar plant, brewery plant for mash filtration, paper mill for paper wastewater dewatering,mining concentrate dewatering,blood product, metallurgy industry, chemical industry, medicine industry, food industry, food additives, fruit juice,oil industry

Hangzhou Leo Filter Press Co.,Ltd.

Hangzhou Leo Filter Press Co.,Ltd.