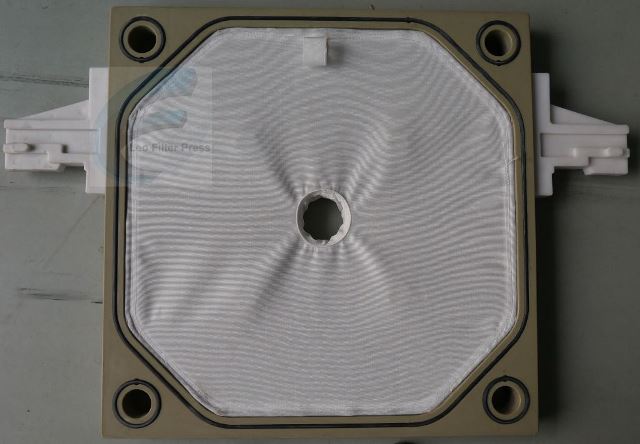

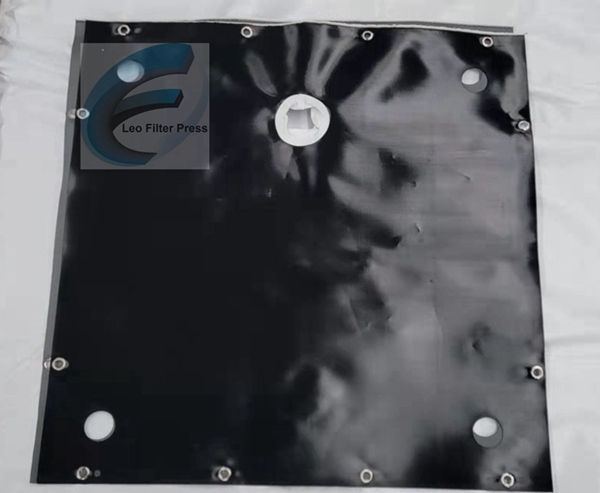

Leo company's product prototype.

Key Features of Leo Filter Press Filter Cloth:

Common Filter Press Filter Cloth Fabric Material:

Polypropylene (PP) – Common, cost-effective, resistant to acids and alkalis.

Polyester (PET) – Good for high-temperature applications, strong mechanical properties.

Nylon– Excellent abrasion resistance, suitable for fine filtration.

PVDF (Polyvinylidene Fluoride) – Highly chemical-resistant, used in harsh environments.

Leo Filter Press Filter Cloth Weave Types:

Plain Weave: Tight structure, good for fine particles.

Twill Weave: More flexible, better cake release.

Satin Weave: Smooth surface, reduces clogging.

Mesh Weave: For coarse filtration.

Leo Filter Press Filter Cloth Surface Treatment

Calendared (Smoothed)– Reduces blinding, improves filter cake release ability

Non-calendared – Higher permeability for faster filtration.

Leo Filter Press provides versatile filter cloths compatible with an extensive range of filter press plate sizes, including 400mmX400mm to 2000mmX2000mm. Additionally, Leo Filter Press offer bespoke OEM services to tailor filter cloths for unique user requirements and special sizes.

In tandem, Leo Filter Press supplies Non-woven Filter Felt designed for gas filtration applications, available in materials such as PE, PP, Antistatic Fiberglass, PPS, Nomex-Aramid, P84, PTFE, and PPS-PTFE, amongst others.

Leo Filter Press provides a diverse selection of filter press cloths, suitable for various filter press plates and sludge press.Choose from caulked gasket or non-gasketed options, along with specialized cloth sheets for plate and frame filter presses.

For an array of industrial filtration applications, Leo Filter Press offers tailored filter cloth solutions. From palm oil and clay filtration to wastewater treatment and beer mash filtration, Leo filter press cloths are engineered to enhance efficiency across industries.

Hangzhou Leo Filter Press Co.,Ltd.

Hangzhou Leo Filter Press Co.,Ltd.