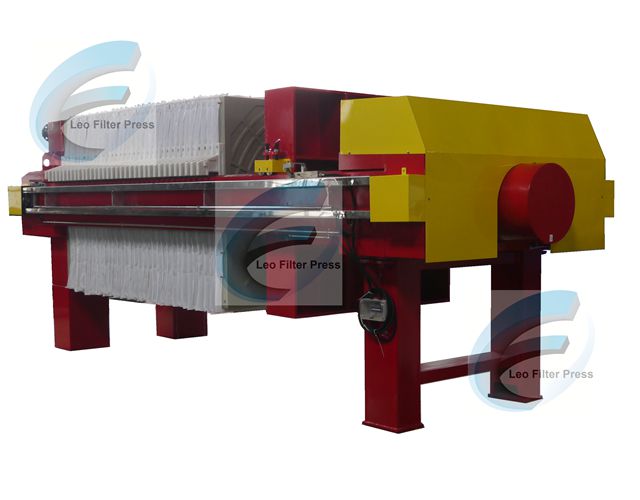

Leo company's product prototype.

Leo Filter Press Chamber Filter Press Design and Operation Instructions:

1.Filter Press Plates:

Chamber filter press will only have one filter press plate type: chamber filter press(chamber recessed plate filter plate/recessed filter plate)

Leo Filter Press chamber filter plates typically made of polypropylene, stainless steel, or other durable materials.

Leo Filter Press chamber filter plate size: 400mm*400mm,470mm*470mm,500mm*500mm,630mm*630mm,800mm*800mm,900mm*900mm, 1000mm*1000mm, 1200mm*1200mm, 1250mm*1250mm, 1500mm*1500mm, 1600mm*1600mm to 2000mm*2000mm or other special OEM order filter plate size

2.Filter Press Cloth: the filter cloth will be covered at the both side of chamber filter plate,Leo

Filter Press offer various filtering mesh and material filter cloth for chamber filter press operation.

3.Filter press frame: filter press frames offer unparalleled strength and durability, featuring an

anticorrosion surface treatment for enhanced longevity and will be different design for various industrial chamber filter press operation.

4. Filter Press Hydraulic System: Leo Filter Press hydraulic system incorporates top-tier electrical oil motors and electrical components for chamber filter press smooth operation. Leo Filter Press chamber filter press hydraulic pistons, made from specially treated steel #45, boast enhanced anti-wear characteristics and exceptional hardness.

6. Filter Press Electric control System: of the Leo Filter Press is equipped with premium electrical components, enabling seamless automation.Leo Filter Press electrical controlling system supports automatic filter press closing and oepning, cylinder closing pressure maintenance, and effortless operation, ensuring that the chamber plate filter press operates with utmost efficiency and minimal intervention.

7. Filter press feed pump:At Leo Filter Press, we provide an array of filter press pumps, each tailored to meet different models and capacities for our Leo chamber plate filter press operations. Discover our pumps that deliver superior efficiency and reliability, perfectly complementing our chamber filter presses. Leo Filter Press offers membrane pump,diaphragm pump,screw pump,slurry pump,piston pump,plunger pump for various slurry feeding and filtering.

5. Other filter press system: for different chamber filter press service industries, Leo Filter Press offer other additional filter press auxiliary systems for filter press operation: automatic drip tray collecting system,automatic filter cloth washing system, automatic filter plate cleaning system,automatic filter cake transporting system … and other OEM systems for chamber filter press operation.

6. Leo Filter Press chamber filter press advantage: high working efficiency for various industries solid liquid separation; high solid content of the filter cake after filtration; suitable for a wide range of industries and applications,such as wastewater treatment plants,mining and mineral slurry processing,chemical and pharmaceutical industries,food and beverage production,oil and gas industry.

Hangzhou Leo Filter Press Co.,Ltd.

Hangzhou Leo Filter Press Co.,Ltd.